Magnetic Pumps

Magnetic chemical pumps are made of PP- PVC- PVDF materials. By clicking on the links below, you can enter the magnetic pumps section and select.

What types of pumps are magnetic pumps?

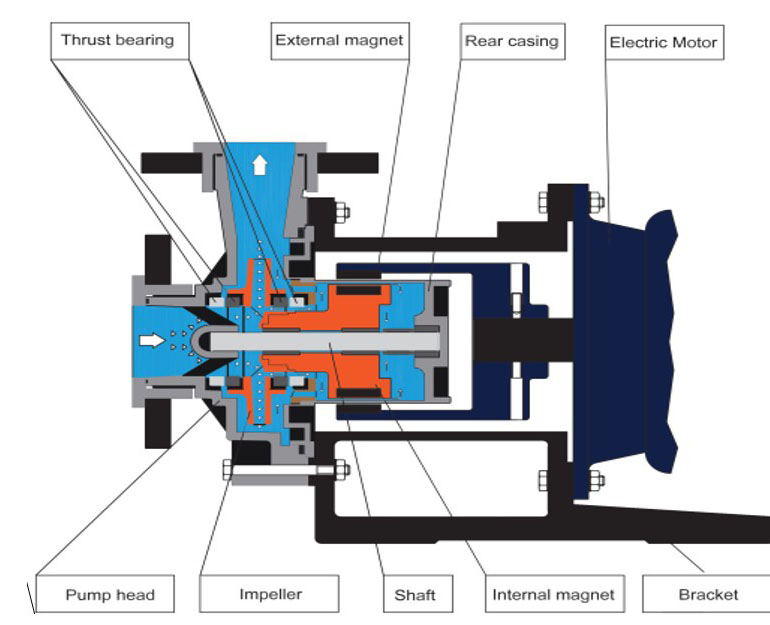

This type of pump is actually a centrifugal pump that transfers motion from an electric motor to an impeller through a magnetic field.

Magnetic pumps are originally designed to pump toxic and hazardous fluids without the use of mechanical seals.

Magnetic pumps are widely used in agricultural, industrial, chemical, medical, health, and food industries that require the transfer of special, low- Viscosity liquids without solids.

One of the problems in the pump industry is the mechanical seal. Mechanical seals, and Gland Packing (Yarn and Graphic), and other seals may eventually fail and Leak after over time, and this problem can cause problems both in terms of operation and in terms of the environment.

One of the best solutions to prevent pump leakage and the resulting problems is to use a magnetic pump.

The moving parts of a magnetic pump do not have any wear or corrosion due to the lack of contact with other components.

One of the problems in the pump industry is the mechanical seal. Mechanical seals, and Gland Packing ( Yarn and Graphic ), and other seals may eventually fail and Leak after over time, and this problem can cause problems both in terms of operation and in terms of the environment.

One of the best solutions to prevent pump leakage and the resulting problems is to use a magnetic pump.

The moving parts of a magnetic pump do not have any wear or corrosion due to the lack of contact with other components.

The structure of magnetic pumps is such that there is no direct connection between the electric motor and the pump impeller, and the impeller moves due to the magnetic field. This practically eliminates Eliminate the need for sealing, and completely eliminates the problem of leakage.

The principle of operation of a magnetic pump is that an internal chamber containing a set of magnets that have permanent magnetic properties is used, and the external shaft that is connected to the impeller and contains a set of permanent magnets and is lubricated by the fluid itself, and with the rotation of the electric motor, the magnetic flux of these magnets moves the impeller.

Today, magnetic pumps are made of various metal materials such as cast iron, bronze alloys, various types of stainless steel, even duplex and super duplex, and also custom-made from various titanium alloys and even ceramics and glass. However, the most common applications in small and medium-sized industries are pumps made of various refinery polymers including PTFE, PE, PVC, PP, and PVDF.

To reach more about these materials, you can access the properties of these materials by clicking on the link below.

Advantages of magnetic pumps:

The advantages of using magnetic pumps include:

- No fluid leakage into the environment

- No waste of valuable fluids in the pump

- Low noise

- Using the pumped fluid itself as a lubricant

- Simple structure and easy maintenance

- No effect of high suction pressure on the thrust shaft force

- Ability to pump special fluids

Applications of magnetic pumps:

Magnetic pumps are used for the following fluids due to their lack of leakage:

Toxic fluids – Chemical fluids – Flammable fluids – Volatile fluids

Corrosive and abrasive fluids – Smelly fluids – Environmentally harmful fluids

Fluids containing radioactive materials – Two-phase fluids and liquefied gases

Fluids under pressure or under vacuum – Expensive fluids.

These pumps are sometimes also used for high and low temperatures.

special materials on a customized basis.

In totally: Corrosive acids, Alkalis, Solvents, Brines, Plating solutions, Sterile solutions,

And other mildly corrosive chemicals and solutions that are compatible with the pump’s material of construction

Currently, Gol Pump Company has pumps made of high-consumption base petrochemical materials in its warehouse and will also be available to customers for other pumps with special materials on a customized basis.

Polymer magnetic pumps have all the properties of acid-resistant polymer pumps, depending on the polymer used in the construction of the pump.

Polymer centrifugal pumps are made for pumping various chemical fluids, solvents, acids, alkaline and depending on the type of materials used, such as polypropylene PP, polyvinyl chloride PVC, polytetrafluoroethylene (Teflon) PTFE, polyvinylidene fluoride PVDF.

Available Models

Important points in use

The points that should be reviewed before using a magnetic pump include:

- The temperature is not high

- The fluid is not crystallized and hardened

- The effect of high viscosities in the fluid

- The motor is not too large because it causes parts to separate from each other during acceleration

- The absence of too much gas in the fluid

Note that in some designs, solid particles suspended in the liquid, which cause wear of bearings and bushings, accumulate inside the chamber and block it. In this case, it is better to use a filter to separate the particles.

Maintenance and troubleshooting of magnetic pumps

Most problems with pumps without mechanical seals occur when the pump runs dry because the pumped fluid lubricates and cools the internal bearings and bushings. In this case, the bearings and bushings also run dry and their hard and brittle materials, including silicon carbide, are damaged in a few seconds.

However, materials such as silicon graphite carbide and Ceramic may run dry for 10 minutes without problems, therefore, preventing a magnetic pump from running dry reduces its maintenance costs.

These pumps have a magnetic coupling and therefore the impeller rotating shaft is not sealed,

If the impeller is locked due to foreign objects in the fluid despite the motor running, the separation of the coupling will stop the impeller from rotating, although the pump may not burn out immediately in this case, it is better to turn off the motor immediately.

The motor is equipped with an overload protection system that automatically turns off the motor if the coil temperature increases and turns it on again when the temperature decreases to the set value.

MD model magnetic pumps are not self-priming and it is better to always install them in a place where their inlet is below the water level of the tank.

Avoid pumping mud and sewage with abrasive materials because they cause premature wear of the bushings.